Fadhili GIP Fixed Facility Expansion & Rich MEG – Condensate Pipeline Installation

Staterra, only recently, have completed a NCEC approved EIA Study Report to facilitate acquisition of the Permit to Construct on behalf of a major petroleum company in KSA.

The EIA was completed in two phases, one for the Gas Processing Facility expansion located 350 km northeast of Riyadh, and the second for a combination of Rich MEG and Condensate pipeline linear installation.

Both EIAs were preceded by extensive comprehensive baseline investigation(s) (i.e. ambient air / emissions to atmosphere / soil and groundwater characterisation / noise assessment and biodiversity studies) to acquire the necessary EIA Field Metrics along with the engineering design information generated during pre-FEED and FEED phases on behalf of the client’s Project Management Team – PMT and Environmental Protectorate Department -EPD.

Based upon the success of that study and the production of all Engineering Procurement Contractor – EPC environmental and social guidance documentation (ESMMP/CEMP/CWMP/ESA&ICR and ENVID), Staterra were further awarded a secondary specific EIA for the EPC contractor responsible for the $7.7 Billion USD GIP expansion covering the following aspects, namely:

- Water delivery systems including fresh water/sea water intake pumping facilities and pipelines.

- Water planning and treatment including raw water treatment, utility & potable water systems, sea water desalination and demineralisation.

- Cooling water systems including cooling towers, tempered water systems, chilled water systems, etc.

- Steam generation, waste heat recovery, co-generation and steam/energy balance & optimisation.

- Steam condensate recovery & treatment.

- Power generation including steam turbogenerators, gas turbine driven generators, diesel generators.

- Fuel treatment systems; fuel gas/natural gas systems, diesel, fuel oil.

- Liquid nitrogen storage and vaporisation.

- Air compressors, air treatment & drying, air separation units and nitrogen, hydrogen & oxygen production.

- Central chemical storage, loading/unloading and chemical injection skids.

- Wastewater treatment system and integration with other utility systems to incorporate the Zero liquid discharge (ZLD) requirement.

- Treated water evaporation ponds, sludge dewatering, drying and handling systems.

- Flare systems including elevated flares, ground flares, thermal oxidisers, etc.

- Onsite and offsite storage tanks including fixed roof, floating roof tanks, cigar tanks, spheres, cryogenic storage, boil off gas recovery systems, gasoline blending and dying systems.

Staterra’s commission is therefore to undertake an Environmental Gap analysis of the original EIA and assess whether it has been impacted by subsequent design changes identified specifically for the Utilities and Offsites EPC Package. Staterra will offer our environmental consultancy services to acquire the necessary NCEC permit to operate – PtO following production of the key Operational Environmental Monitoring & Management Plan – OEMMP document.

It is both Staterra’s privilege and honour to assist major blue chip petroleum companies in fulfilling their shorter to midterm expansion plans in KSA and throughout the MENA Region to provide the necessary fossil fuels, and their collective processing in particular cleaner burning LNG, to keep the global economy’s engine ticking over whilst they make the longer-term transition to supporting renewable energy source developments for KSA in support of In Kingdom efforts towards a more circular economy and enhanced global sustainability as set out in the Saudi Green Initiative for 2030.

Epilogue: How did Staterra achieve such success?

The takeaway message from any successful commission is based upon one central aspect that being ‘communication’. More succinctly, key aspects of communication between all parties involved namely:

Aspect 1: The ultimate Oil and Gas Company undertaking the mega project expansion IK and clear communication between their Project Management Team (both Out of Kingdom and In Kingdom) as well as communication with their Environmental Protectorate Department who oversee all technical aspects of the expansion commission and ensure compliance with their own Engineering Standards and Procedures particularly in regard to EIA Production;

Aspect 2: Communication between the Civil Engineering Company tasked with preparation of all Basis of Engineering Design and all pre–Front End Engineering design and FEED documentation in all departments including design engineering, process engineering, chemical; engineering, utilities and construction and pre-commissioning and commissioning including handover to operations. Moreover, this includes all queries for multiple parties are being responded to in a timely and comprehensive manner from offices both in the UK and in Saudi Arabia;

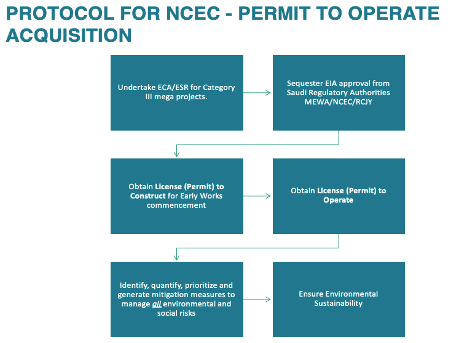

Aspect 3: Vital aspects of communication by Staterra, on behalf of the client, with the National Centre for Environmental Compliance to ensure clear passage for each of the three keys phases of EIA Production namely:

a) Environmental Classification Application submission (establishment of project programme of works as either a Category 1,2 or 3 level designation from least stringent to most)

b) Generation, as required of the Environmental Scoping Report which sets out the roadmap or pathway for EIA Study Report preparation.

c) Provision of the final EIA Study Report to the ultimate client and civil engineering firm for technical review and agreement responding to any and all technical and or regulatory queries which may arise.

d) Provision of all supplementary Engineering Procurement and Construction Contractors environmental and social guidance documentation including:

- Operational Environmental Monitoring & Management Plan – OEMMP.

- Construction Environmental Management Plan – CEMP

- Construction Waste Management Plan – CWMP

- Environmental Social Aspects & Impacts Commitment Register – ESA&ICR

- ENVID Workshop and Report

- Air Dispersion Modelling Report – AERMOD

- Groundwater Modelling – MODFLOW /eFLOW

- Green House Gas Register

- Noise & Vibration Assessment Report – SoundPlan

All of the aforementioned studies and management plans form part of the EIA Study Report to be submitted to either the NCEC or the Royal Commission of Jubail, Yanbu, Al Khair and Jizan which is invariably project location dependent.

So, in summary, it is the Staterra’s ultimate capability of adhering to clear and concise milestones and deliverables over a realistic time frame that is all import from proposal generation through to Kick Off Meeting through to EIA Final production in order to obtain ultimate NCEC EIA Approval which is the precursor to Permit to Construct issuance to enable initiation of all project Early Works and begin construction in earnest. Upon construction, commissioning and handover completion the Permit to Operate is then applied for to the relevant Saudi Regulatory Authority bodies.

At Staterra, our objective is to become the premier environmental consultancy in KSA and MENA Region and to fulfil our overall corporate business objective of taking our clients ‘Beyond Compliance’.