Securing environmental excellence: Advanced Treatment Unit expansion in Jubail

You’re expanding critical wastewater infrastructure in one of Saudi Arabia’s most regulated industrial zones. Your project timeline hinges on environmental permits, and the Royal Commission’s requirements are extensive. Any misstep could delay construction for months.

A leading industrial waste management provider in Jubail faced exactly this challenge. They needed to add an Advanced Treatment Unit to their existing facility expansion in Jubail Industrial City. The facility would handle high-volume industrial wastewater streams, with high-temperature biological and chemical sludge processing. Odour concerns. Noise impacts. Groundwater protection. All requiring comprehensive environmental assessment before breaking ground.

Staterra was appointed as the approved third-party environmental consultant to deliver the complete environmental permitting package and secure the Environmental Permit to Construct (EPC) that would keep the project on schedule.

The challenge: complex infrastructure, tight timelines

The client operates in Jubail Industrial City, where the Royal Commission Environmental Regulations (RCER-2015) set some of the region’s most stringent environmental standards. Their expansion project involved:

- Treatment Capacity: high-volume operational lines designed for continuous industrial processing.

- Process Technology: automatic pH regulation, coagulation, flocculation, Dissolved Air Flotation (DAF), and anaerobic heat treatment.

- Waste Outputs: significant annual volumes of hazardous sludge cake and treated wastewater.

- Location Sensitivity: an industrial zone with existing air quality monitoring and strict discharge standards.

The challenge? RCER-2015 requires comprehensive environmental impact assessment for Type II facilities – facilities with moderate environmental impact potential. The client needed to demonstrate minimal impact through rigorous baseline data, impact modelling, and mitigation planning.

And they needed it fast.

Our approach: comprehensive assessment, clear results

We mobilised our team to deliver a complete Permit Application Package (PAP) addressing every RCER requirement. Here’s how we worked alongside the client to get it done.

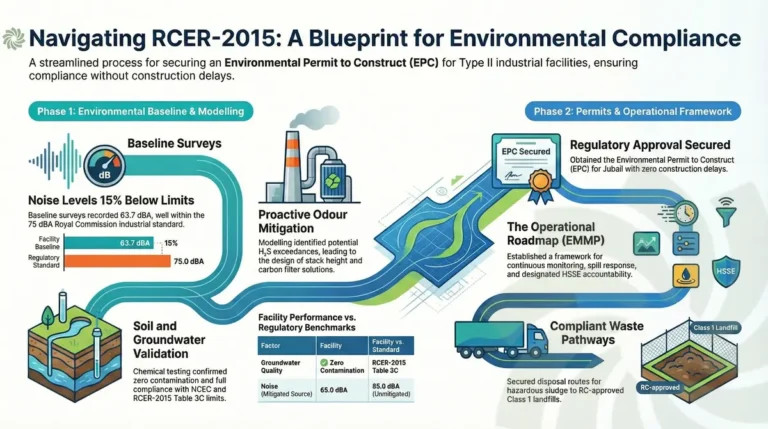

Establishing environmental baselines

You can’t assess impact without knowing where you’re starting. Our team conducted detailed baseline surveys across multiple environmental factors:

- Air Quality & Odour: utilised data from Royal Commission Air Quality Monitoring Station #6. Confirmed ambient compliance for SO₂, NO₂, and CO with RC standards. Conducted specific modeling for Hydrogen Sulphide (H₂S), Ammonia (NH₃), and VOCs.

- Key finding: H₂S concentrations predicted slightly above the odour detection threshold near the source.

- Noise Impact: surveyed numerous locations along facility boundaries. Baseline maximum was 63.7 dBA – well below the 75 dBA Royal Commission standard for industrial areas. Identified the primary operational noise source as a diesel generator.

- Soil & Groundwater: collected samples from groundwater monitoring wells and soil locations. Laboratory analysis showed zero visual contamination, and chemical testing confirmed full compliance with NCEC standards and RCER-2015 Table 3C limits. Groundwater depth was confirmed at 4-5 meters with no contamination detected.

Impact modeling: predicting real-world performance

Baseline data is one part of the story. Predictive modeling shows how your facility will perform once operational.

We used internationally accepted methodologies – US EPA Emission Factors and SCREEN3 atmospheric dispersion models – to predict environmental impacts:

- Atmospheric Dispersion Modeling: calculated H₂S dispersion patterns under various meteorological conditions. Identified potential exceedance of odour detection thresholds at the fence line and developed a mitigation strategy involving increased stack height and enclosed systems with carbon filters.

- Noise Propagation Study: modeled noise propagation without mitigation (85 dBA at source). Recommended acoustic enclosures to reduce levels to 65 dBA at source.

- Result: cumulative noise at the fence line remains negligible, well within regulatory limits.

- Groundwater Impact Assessment: evaluated contamination risk from process operations. Facility design includes paved process areas with engineered drainage systems.

- Risk assessment conclusion: low groundwater contamination potential.

“H₂S concentrations predicted slightly above detection thresholds – we identified the challenge early and designed mitigation that works.”

Comprehensive waste management planning

Your waste doesn’t disappear; it needs a compliant disposal pathway. We developed a detailed Waste Management Plan outlining every waste stream:

- Hazardous Sludge Cake: stabilised and transported to an RC-approved Class 1 landfill.

- Treated Wastewater: discharged to the existing evaporation pond within the facility boundary.

- Sanitary Wastewater: collected by tanker and sent to the Central Sanitary Wastewater Treatment Plant.

Each pathway meets RCER-2015 requirements. Each disposal method is documented and approved.

Environmental Management & Monitoring Plan (EMMP)

Compliance isn’t just about meeting standards today; it’s about maintaining them tomorrow. We created an EMMP that serves as the operational framework for ongoing environmental management.

Key Components:

- Staffing & Accountability: designated Health, Safety, Security & Environment (HSSE) Manager with clear responsibilities for auditing and incident reporting.

- Monitoring Protocols: continuous fence-line odour monitoring; indoor air quality checks; monthly analysis of treated wastewater; annual groundwater monitoring.

- Training Requirements: mandatory environmental induction, spill response procedures, and waste segregation protocols for all personnel.

The deliverables: everything the client needed

We delivered the complete environmental permitting package to the Royal Commission:

- Environmental Impact Assessment (EIA) Study: full RCER-2015 compliant assessment demonstrating minimal environmental and social impacts.

- Permit Application Package (PAP): complete application forms with supporting technical documentation.

- Environmental Emergency Response Plan (EERP): framework for incident management and emergency protocols.

- Noise Propagation Modelling Study: quantitative analysis with mitigation recommendations.

- Environmental Management & Monitoring Plan (EMMP): operational roadmap for ongoing compliance.

Client benefits: speed, certainty, operational readiness

- Regulatory Approval Secured: Environmental Permit to Construct (EPC) obtained from the Royal Commission for Jubail with zero delays to the construction timeline.

- Risk Mitigation in Place: odour management strategy addresses H₂S detection thresholds. Acoustic mitigation maintains noise well below regulatory limits. Engineered controls minimise groundwater contamination risk.

- Operational Framework Established: clear environmental management structure with designated HSSE accountability and monitoring protocols integrated into operations.

- Sustainable Compliance: hazardous waste disposal pathways established to RC-approved Class 1 landfills and enclosed building designs to minimise atmospheric emissions.

The outcome: construction ready, future-proofed

The client received their Environmental Permit to Construct on schedule. Construction proceeded without regulatory delays. The facility now operates with a comprehensive environmental monitoring framework that ensures ongoing compliance with Royal Commission standards.

More importantly, the client has a clear roadmap for environmental management throughout the facility’s operational life ,not just a permit, but a proven system for maintaining it.

Need environmental permitting support for your industrial expansion? Whether you’re navigating NCEC requirements, Royal Commission regulations, or international environmental standards, our team delivers the expertise and speed your timeline demands. Let’s talk about your project.